Discover what linear rails are, how they work and where they’re used.

The UK automation sector is growing rapidly, with it valued at around $8.42 billion in 2021 and projected to reach $14.64 billion by 2028. As automation and precision engineering continue to expand, so does the need for reliable linear rails and linear guide systems to keep production lines operating efficiently.

If you’re looking to improve precision, reduce friction and increase reliability in your production process, a linear rail system could be exactly what you need. From automated assembly to packaging and robotics, linear rails are the backbone of efficient, accurate movement across modern manufacturing lines.

In this guide, we’ll explain what linear rails are, how they work, the benefits they bring, and what to consider when choosing the right linear guide system for your application.

What is a Linear Rail and How Do They Work?

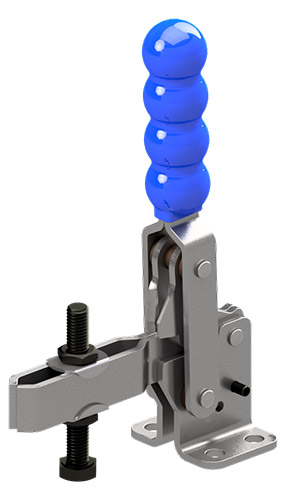

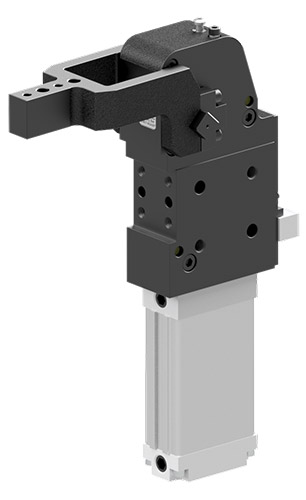

A linear rail system is designed to support the movement and load of a piece of equipment in a straight line, either vertically or horizontally. This simple but effective piece of mechanical equipment allows you to move components smoothly and safely through manufacturing or packaging processes with minimal friction and maximum precision.

The term linear rail is often used interchangeably with linear guide rails, linear guides, linear guideways, linear slides, and linear guidance systems. Whatever you call them, linear rails enable controlled, low-friction motion along a set path, ensuring consistent, accurate positioning across automated and manual systems alike.

What Are Linear Rails Made From?

Linear guide rails are typically made from high-strength, hardened and galvanised steel to resist corrosion. During manufacturing, the metal is cold drawn, shaped and profiled before adding a roller or ball runner. Profiled rail guides are most suitable for high-load applications and provide precise, repeatable linear motion.

Rails are available in a huge range of sizes, from miniature linear rails that move delicate components in confined spaces to heavy-duty systems capable of carrying loads exceeding a ton.

What Are the Common Applications for a Linear Rail?

Because linear rails come in multiple sizes, accuracy grades and preloads, they can be used in almost any industrial environment that requires controlled, precise motion. Their combination of load capacity, travel accuracy and rigidity makes them suitable for a wide range of uses.

Linear rail systems outperform other guide types, thanks to their ability to manage downward, lift-off and moment loads – unlike round shaft guides, which can only withstand downward loads. They also deliver longer travel distances than crossed roller guides, while maintaining exceptional stiffness, rigidity and long service life.

Typical applications for linear guide rails include:

- Automation and robotics systems

- CNC machining and manufacturing equipment

- Packaging and assembly lines

- Automotive production and test rigs

- Precision engineering and inspection systems

Are Linear Rails Worth It?

If your operation depends on accuracy, repeatability and reliability, linear rails are one of the most cost-effective investments you can make. Their long service life and minimal maintenance requirements make them ideal for improving production efficiency and reducing unplanned downtime.

Compared to alternative guidance systems, linear guide rails offer higher load capacities, smoother motion and less wear on components. This translates into consistent quality, faster cycle times and improved safety across your manufacturing processes.

When correctly specified and maintained, a linear rail system can perform for years with minimal servicing – providing excellent value over its lifecycle.

What Are the Challenges of Using Linear Rails?

While linear rails are reliable and versatile, several common challenges can affect their performance. These are easily managed with the right preparation and specification:

- Consider how materials and surface plating affect cost and lead times — specialist coatings may extend manufacturing times.

- Ensure your mounting surfaces are machined to tolerance; even small misalignments can add preload and increase friction.

- Specify preload accurately to minimise vibration, noise, heat and deflection.

- Test across the full run to identify any irregularities early.

- Include mounting features for easy alignment during installation.

Partnering with an experienced supplier like Sandfield Engineering helps ensure your linear guide systems are specified, installed and maintained correctly for reliable long-term performance.

How Do You Choose the Right Linear Rail?

The best approach to specifying and sizing linear rails is methodical. Begin by clearly defining the most important parameters for your application, then narrow down options based on those criteria before refining your final selection.

You should consider:

- Rail profile – square or round

- Bearing type – cantilever or saddle slides

- Stroke, load, speed, and duty cycle

- Mounting area and orientation – horizontal, vertical, wall-mounted or inverted

How Do You Maintain a Linear Rail for Optimum Performance?

Any system with moving parts will eventually wear, but with correct maintenance, your linear rail system can deliver years of trouble-free service. The key is lubrication, inspection and proactive care.

Under-lubricated guides can wear prematurely, leading to friction and performance issues. Proper lubrication reduces wear, vibration and heat, extending the life of both rails and carriages. Some systems use automated lubrication, though they can be complex and costly. Others feature low-maintenance bearings with built-in lubricant reservoirs.

To maintain performance:

- Listen for changes in noise or vibration – these often indicate poor lubrication or misalignment.

- Inspect seals regularly; they keep contaminants out and lubrication in.

- Replace worn parts using interchangeable linear rails and bearings to simplify servicing.

Routine checks and preventive maintenance will keep your linear guide rails performing efficiently and reduce downtime.

Where to Buy Linear Rails

For high-performance linear rails and guide systems, trust Sandfield Engineering. As one of the UK’s longest-serving suppliers of industrial automation products, we can help you find the right solution for you.

We stock a wide range of linear rails, linear guideways and accessories, all available on short lead times. Whether you need a miniature rail for compact equipment or a heavy-load linear rail for demanding environments, our team can recommend the perfect system for your application.

Explore our Linear Rails product range or contact us directly for advice on custom specifications.

Any Questions About Linear Rails?

We know everything there is to know about Linear Rail Systems and hold stock which is available on short lead times.

If you have questions, please do not hesitate to call + 44 330 223 5344 or email sales@sandfieldengineering.com. We’ll be more than pleased to answer them for you.