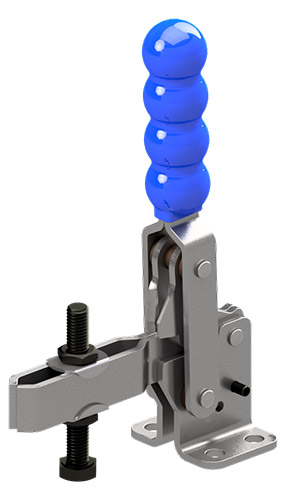

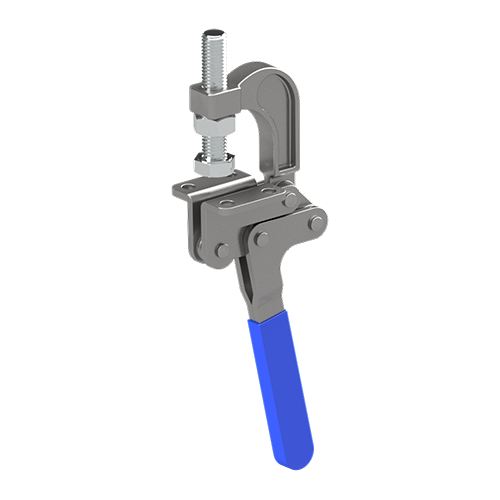

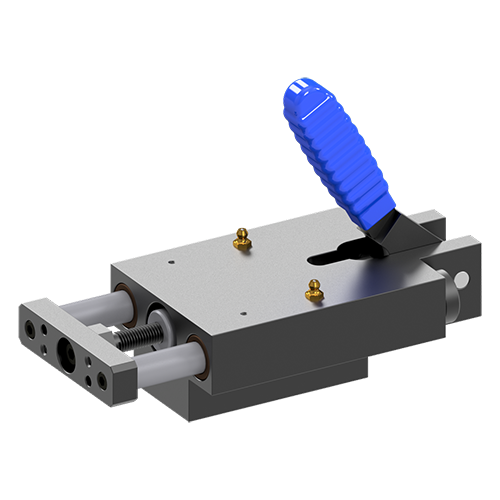

The advantage of a toggle clamp is that it is quick and easy to use and the geometry of the clamp levers and pivots provide high clamping forces.

Strap clamps and G clamps or sash clamps take longer to set up and often don’t provide enough holding force needed.

As well as holding forces, toggle clamps improve efficiency, speeding up production output.

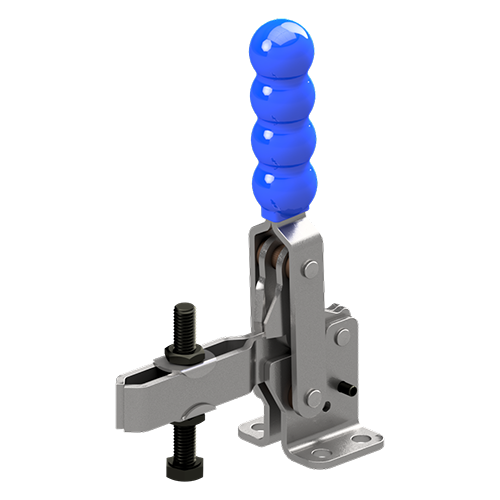

Our clamps: endurance and reliability

At Sandfield Engineering, we pride ourselves on the durability of our toggle clamp range. One of our first projects was for the Mini car at the Longbridge plant in the late 1950s: we provided hundreds of clamps for its assembly lines.

When the plant was decommissioned in 2000 after three million cycles, more than 70% of the original steel toggle clamps we installed on those assembly lines were still in perfect working order.