Diodes saves 300 jobs at Greenock’s ex-Texas Instruments facility

As reported by the Herald Scotland, the massive US firm Diodes is planning to invest £47 million to upgrade the Greenock-based semiconductor manufacturing plant it bought from Texas Instruments in 2019. The plan is to transform it into a facility to develop sophisticated microchips, and they’re taking advantage of a £13.7 million grant from Scottish Enterprise to help fund the changes. The plant employs 300 people and it’s great news since there have been uncertainties around the its survival.

In 2016 Texas Instruments announced plans to close the facility and shift production to more modern facilities overseas, taking advantage of lower production costs. In Diodes’ opinion the Greenock plant is the perfect facility to support competing in the fast-moving global computer chip market. The chips manufactured there are due to be sold into a wide range of sectors, including mobile electronics and vehicles.

New UK nuclear fusion opportunities

Nuclear fusion is a reaction in which two or more atomic nuclei are combined to form one or more different atomic nuclei and subatomic particles. The difference in mass between them generates huge amounts of clean energy. Fusion could provide a cheap, safe, clean, abundant and reliable source of energy but so far scientists haven’t managed to make it happen. It’s easier said than done.

According to PES Media the government research organisation responsible for developing nuclear fusion – the UK Atomic Energy Authority – is offering more opportunities to players in the UK manufacturing and engineering sector, and they’ll be showcasing them via a series of special supply chain events through 2020.

The news emerges against a landscape where, in 2019, the prospects for developing nuclear fusion as a reliable source of clean energy came a few steps closer. The resulting increased Government investment in fusion, and in various new test centres working with academic and industrial partners, mean there are plenty of exciting projects to get involved with.

Initiatives on the cards include STEP, the UK’s fusion power plant project, plus RACE, the Authority’s robotics centre, the exciting New Fusion Technology Facilities at Culham and Rotherham, the H3AT tritium research facility, various exciting opportunities at ITER, the France-based international fusion experiment, and exciting projects at the Culham Science Centre campus.

Meet the world’s most effective lithium sulphur battery

The Engineer reports on the commercialisation of what might just be the planet’s most efficient lithium-sulphur battery. In fact it is so good it’s being tipped to out-perform current top performers more than four times over.

It’s all down to Dr Mahdokht Shaibani from Monash University’s Department of Mechanical and Aerospace Engineering in Melbourne, and his international team, who have developed an ultra-high capacity Li-S battery with a lot less environmental impact than current lithium-ion products.

The battery can, apparently, power to a smartphone for five days, and further testing is on the cards in vehicles and on solar power grids throughout this year in Australia.

How did they do it? The team used the same materials in standard lithium-ion batteries, but they changed the design of the sulphur cathodes to take bigger stress loads without losing overall capacity or damaging performance. The method creates bonds between particles that accommodate stress incredibly well, resulting in levels of stability that no other battery has achieved so far.

It looks like the initiative plays a vital part in what’s going to be a perfect storm: great performance, low manufacturing costs, large supplies of raw material, easy processing and a smaller environmental footprint make the new battery design areal winner.

Tesla woos China

Tesla’s brand new multi-billion-dollar plant near Shanghai, China, marked the US brand’s first venture outside the USA. Now they’re making the first ever China-manufactured Model 3 sedans over there.

China is the biggest existing market for large gas guzzling cars, and Tesla is determined to step into that market with vehicles selling at prices not much higher than locally-made electric cars from brands like NIO and Xpeng Motors. Tesla’s prices in China are already undercutting those of competitors BMW and Daimler.

Musk believes the Model Y crossover model will probably be the best fit for the Chinese market, but they also intend to eventually design a vehicle especially for the Chinese. For the moment Tesla plans to increase production to 150,000 Model 3 vehicles a year, later increasing to 500,000 a year.

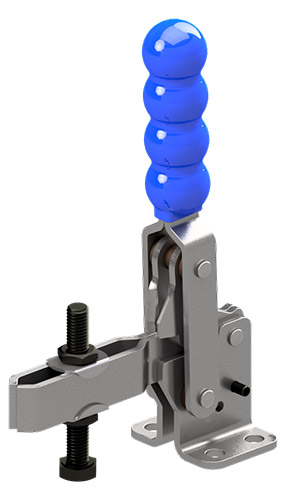

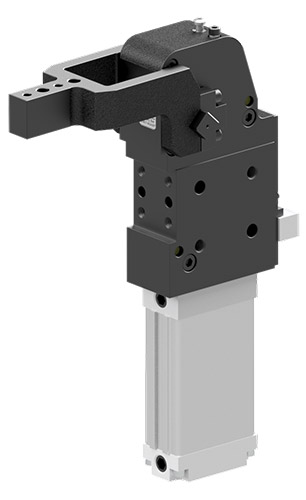

Speak to Sandfield Engineering about your manufacturing challenges

Please do not hesitate to call Sandfield Engineering on +44 (0)330 223 5344 or email sales@sandfieldengineering.com for immediate advice on Industrial Automation Products and Clamping challenges.