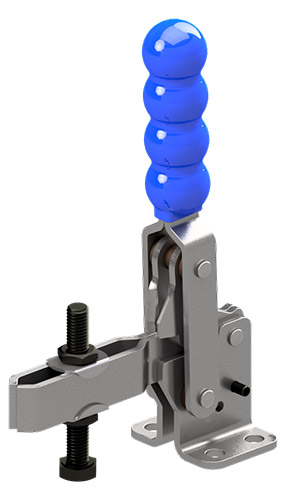

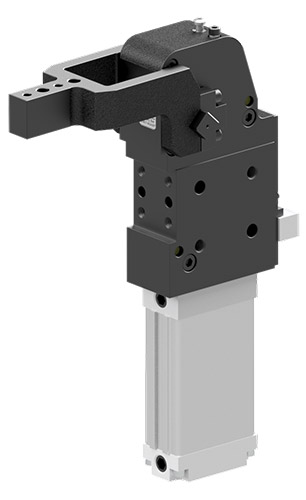

Sandfield Engineering are experts in clamps, bowl feeders and industrial automation.

We have been delivering high-quality engineering products and services since 1965. In that time our unique experience working with international brands has led to the evolution of products and services that are delivering increased safety, efficiency, quality, productivity and profitability for hundreds of businesses in the UK and internationally.

You can read more about our products and services on this page, as well as our custom engineering offering and environmental solutions.